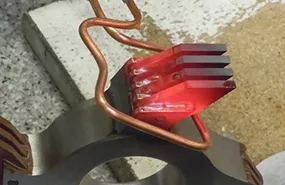

Extended heating with the possibility of welding several elements simultaneously.

Examples: electrical contacts, hard-metal tools.

Power Cube Series 200 Generators

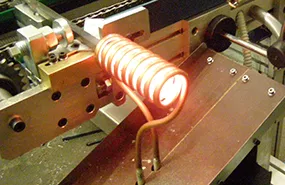

The 200 series is the state-of-the-art in medium-high frequency generators available in the market. This family combine the miniaturized CEIA Heating Head solution (patented) with a powerful, continuous-duty rated generator with so high efficiency that it can replace traditional generators in applications up to double input power, thus cutting the initial investment and operating costs.Key Points

High Power output

High level of performance with minimal operating costs

Compact and integrable Heating Heads

High Safety: all models output isolated from the mains

Continuous generation

Built-in Self-diagnosis

Constant, repeatable power generation via microprocessor control

Highly integrated with a small footprint

State-of-the-art electronics

Interfaces with CEIA Master Controller V3+ unit to manage heating cycles (temperature, time and power)

Compliant with the Regulations on Electrical Safety and Electromagnetic Compatibility

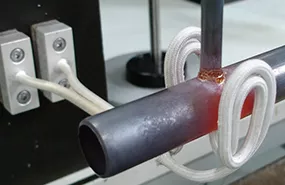

The 90-180-360-720/200 Power Cube generators are com¬plementary to the CEIA family of medium-frequency heat¬ers, being perfectly suited to applications that require very rapid and localized heating. The generators have an ideal design for integration into automatic production systems. Space efficiency and simple operation also make these gen¬erators perfect for manual applications.

All CEIA Power Cube Generators can be combined with the CEIA Master Controller V3+ unit. They can even be inter¬faced with PCs or programmable controllers via their analog and RS-232 interfaces.

The use of innovative technology and latest-generation components places the 200 series generators in a class of their own in terms of performance, power output and opera-tional cost.

All CEIA Power Cube Generators can be combined with the CEIA Master Controller V3+ unit. They can even be inter¬faced with PCs or programmable controllers via their analog and RS-232 interfaces.

The use of innovative technology and latest-generation components places the 200 series generators in a class of their own in terms of performance, power output and opera-tional cost.

| Power Cube 90/200 | Power Cube 180/200 | Power Cube 360/200 | Power Cube 720/200 | ||

| Input / Output | Maximum absorbed power | 6,0 kW | 12,0 kW | 24,0 kW | 48,0 kW |

| Average output power at inductor | 90 kVAR | 180 kVAR | 360 kVAR | 720 kVAR | |

| Supply voltage | 400 Vac ±10% 3~ 50/60 Hz | ||||

| Water cooling | pressure: 300 kPa - flow: 1,5 l/min | pressure: 300 kPa - flow: 2 l/min | pressure: 300 kPa - flow: 3 l/min | ||

| Operating conditions | Operating temperature | + 5 ÷ + 55 °C | |||

| Storage temperature | - 25 ÷ + 70 °C | ||||

| Relative humidity | 0 ÷ 95 % (without condensation) | ||||

| Frequency Range | 150 kHz...220 kHz | 150 kHz...220 kHz | 150 kHz...220 kHz | 150 kHz...220 kHz | |

| Dimensions | Generator | 195 mm x 304 mm x 426 mm | 490 mm x 496 mm x 768 mm | 600 mm x 650 mm x 1280 mm | |

| Heating head | 120 mm x 200 mm x 170 mm (HH17) 80 mm x 120 mm x 197 mm (HH17C) | 120 mm x 213 mm x 200 mm (HH18) | 120 mm x 274 mm x 200 mm (HH19) | ||

| Inductor holder | 150 mm | 150 mm | 150 mm | ||

| Weight | Generator | 21 kg | 90 kg | 190 kg | |

| Heating head | 8.4 kg | 10.5 kg | 20 kg | ||

| Conformity | Complies with international standards currently applicable for Electrical Safety (EN 60204-1) and Electromagnetic Compatibility (EN 55011, EN 61000-6-2) | ||||