The 900 HI-PE series of High Frequency Generators spans five models with a power rating range of 2.8 to 6 kW. They combine the miniaturized CEIA Heating Head solution (patented) with a powerful, continuous-duty rated generator with so high efficiency that it can replace traditional generators in applications up to 12kW, thus cutting the initial investment and operating costs.

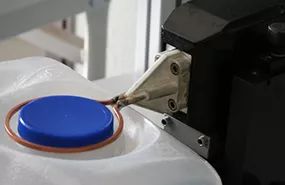

Cap Sealing

Induction cap sealing is a fundamental process within the packaging industry, primarily engineered to forge a secure bond between a protective foil liner and the periphery of a container. This precisely formed hermetic seal fulfills multiple critical functions: it provides clear tamper indication, effectively prevents egress of contents, and substantially contributes to preserving product integrity and extending shelf stability. The resultant hermetically sealed state is vital for product safety and quality assurance, adhering to a rigorous hermetic seal definition.

The operational principle of this process centers on generating a high-frequency electromagnetic field to induce heat within the conductive foil liner beneath the cap. As the container traverses beneath the induction coil (an integral induction heating coil and often the core of an induction coil heater), the foil rapidly undergoes resistive heating. This thermal energy causes the polymer layer on the foil to liquefy and subsequently create a permanent seal with the container's rim. This heating process is characterized by its speed, non-contact nature, and highly localized energy transfer, thereby minimizing thermal exposure to both the cap material and the enclosed contents.

Paramount precision and consistent repeatability are critical, as the sealing event must be executed within extremely short temporal windows typical of high-speed manufacturing lines. Inadequate thermal input can lead to seal failures and subsequent product leakage, while excessive heating may induce deformation of the packaging substrate. Therefore, robust power regulation, stable thermal performance, and seamless integration with automated production systems are key determinants of process success.

CEIA's high-frequency induction systems (induction heaters) are frequently specified for cap sealing applications due to their remarkable energy efficiency, fine-grained power adjustment capabilities, and sophisticated control interfaces. These attributes enable consistently reliable performance even under the most demanding production parameters. Due to its inherent rapidity, cleanliness, and proven reliability, induction cap sealing remains a preferred methodology across diverse industrial applications requiring secure and consistent closure