The 900 HI-PE series of High Frequency Generators spans five models with a power rating range of 2.8 to 6 kW. They combine the miniaturized CEIA Heating Head solution (patented) with a powerful, continuous-duty rated generator with so high efficiency that it can replace traditional generators in applications up to 12kW, thus cutting the initial investment and operating costs.

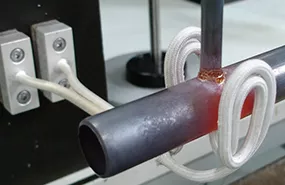

Hard Brazing

Hard brazing, also frequently termed high-temperature brazing, is a sophisticated metal-joining process that leverages a filler metal characterized by a melting point in excess of 450°C, typically within the 600°C to 1200°C range. This methodology establishes a highly durable bond between two or more metallic components. Fundamentally distinct from welding, brazing ensures the base materials remain in their solid state. Instead, the molten filler metal is drawn into the joint interface through capillary action, culminating in a robust, hermetically sealed connection, thereby creating an airtight seal.

This technique is optimally engineered for joining dissimilar metals, such as carbon steel to copper, copper to copper, copper to brass or specifically to bond stainless steel to stainless steel. Its utility spans critical industrial applications including the automotive, aerospace, HVAC, and electrical manufacturing sectors. Joints formed through hard brazing are meticulously designed for superior mechanical strength, augmented corrosion resistance, and an inherent capacity to endure elevated temperatures and pressures. What is a braze becomes clear through these resulting properties.

Achieving precise thermal management and uniform heating is paramount in the brazing process to ensure optimal filler metal flow and uncompromised joint integrity, simultaneously mitigating overheating or degradation of the parent materials. Induction heating is exceptionally well-suited for this demanding application, offering rapid, highly localized, and repeatable heating with minimal thermal distortion to adjacent components. The design of an induction heater is crucial for enabling such precision in the heating process.

CEIA induction heating systems (induction heaters) are engineered to support this rigorous brazing process by furnishing stable and accurate inductive heating. In addition CEIA offers optical pyrometers for the control of the temperature that, combined with the induction generators, can grant a repeatability an higher quality to the process. This empowers operators to consistently achieve high-quality brazing results across a diverse spectrum of materials and intricate component geometries, unequivocally demonstrating the efficacy of inductive heating in industrial applications.