The 900 HI-PE series of High Frequency Generators spans five models with a power rating range of 2.8 to 6 kW. They combine the miniaturized CEIA Heating Head solution (patented) with a powerful, continuous-duty rated generator with so high efficiency that it can replace traditional generators in applications up to 12kW, thus cutting the initial investment and operating costs.

Heating Treatment

Heat treating constitutes a fundamental thermal process engineered to meticulously alter the physical and mechanical characteristics of metallic materials. Its primary objectives typically involve enhancing hardness, augmenting wear resistance, alleviating detrimental internal stresses, or improving ductility. This methodology is extensively deployed across diverse manufacturing applications, including but not limited to the automotive, aerospace, toolmaking, and heavy equipment industries.

Conventional heat treatment regimes encompass hardening, tempering, annealing, normalizing, and stress relieving. These sophisticated methods mandate meticulously controlled heating and cooling cycles, frequently requiring adherence to specific temperature profiles, precise durations, and controlled cooling rates, all meticulously tailored to the material's composition and the desired metallurgical outcome. The process of annealing metal, for instance, is highly controllable. This includes specialized processes such as annealing copper or annealing of stainless steel. These represent key metal hardening techniques.

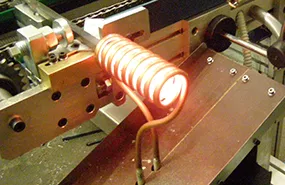

Induction heating has emerged as a premier methodology for heat treating due to its inherent speed, exceptional precision, and superior energy efficiency. It enables highly localized heating, rendering it unequivocally ideal for surface hardening or treating specific zones of a component—such as gear teeth, shaft surfaces, and bearing interfaces—without adversely affecting the bulk material's core structure. This targeted hardening process is a significant advantage. Furthermore, the process is inherently clean, highly repeatable, and readily amenable to automation, thereby perfectly supporting contemporary high-volume production environments.

Induction heat treating delivers demonstrable improvements in component performance, significantly reduced distortion, and elevated production throughput, thereby cementing its status as a vital process in high-precision manufacturing and industries with stringent performance demands.

CEIA induction systems (induction heaters) are specifically designed to provide rapid, highly efficient heating coupled with meticulous control, rendering them perfectly suited for executing complex heat treatment cycles