The 900 HI-PE series of High Frequency Generators spans five models with a power rating range of 2.8 to 6 kW. They combine the miniaturized CEIA Heating Head solution (patented) with a powerful, continuous-duty rated generator with so high efficiency that it can replace traditional generators in applications up to 12kW, thus cutting the initial investment and operating costs.

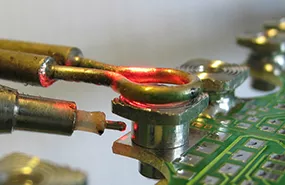

Tin Soldering

Soldering in contemporary industrial environments demands an exceptionally high degree of control, meticulous precision, and robust repeatability, particularly when engaged with delicate electronic components or intricate mechanical assemblies. Successful outcomes are critically contingent upon the accurate management of heat delivery, solder volume deposition, and precise temporal sequencing throughout the entire process. This underscores the importance of a well-controlled heating process.

CEIA Induction heating soldering systems incorporate advanced features engineered for optimal performance, including closed-loop control algorithms, automated solder feed mechanisms, and fully programmable process parameters. These sophisticated capabilities ensure unparalleled consistency across high-volume production runs.

This exacting level of control is fundamental in industries such as electronics manufacturing, automotive production, and electrical component fabrication, where joint integrity, electrical conductivity, and comprehensive quality assurance are unequivocally paramount.

An exemplary advanced solution is CEIA's 900 Series soldering platform. This platform integrates compact, patented solid-state generators with dedicated control units, frequently paired with CEIA's specialized wire-fed solder applicators. These systems are distinguished by their exceptional energy efficiency (exceeding 95%) and their inherent ability to deliver precise, repeatable heat for the consistent formation of robust solder joints. This is a testament to the efficient design of an induction heater for this application.