The 900 HI-PE series of High Frequency Generators spans five models with a power rating range of 2.8 to 6 kW. They combine the miniaturized CEIA Heating Head solution (patented) with a powerful, continuous-duty rated generator with so high efficiency that it can replace traditional generators in applications up to 12kW, thus cutting the initial investment and operating costs.

Tool Brazing

Tool brazing is a specialized metal-joining process engineered for the secure affixation of cutting inserts, carbide tips, or hardened steels to tool bodies such as drills, saw blades, or milling cutters. The paramount objective is to forge a mechanically strong, highly durable joint capable of resiliently withstanding significant mechanical stress and severe thermal loads encountered during operational use. This specific brazing process is crucial for tool longevity. What is brazing in this context refers to this specialized technique.

Fundamentally distinct from welding, brazing does not involve the fusion of the base materials. Instead, it meticulously employs a filler metal that flows into the joint interfaces via capillary action, typically at a melting point ranging between 600°C and 1200°C. This methodology ensures high joint integrity for industrial tools while meticulously preserving the metallurgical properties of both the cutting material and the tool body. This process exemplifies what is a braze.

Precision in heat application is absolutely essential. The heat must be applied rapidly and with extreme localization to prevent compromising the temper of the tool or inducing undesirable internal stresses.

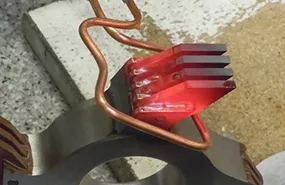

Induction heating is optimally suited for tool brazing due to its intrinsic capability for rapid, precisely targeted heating combined with high repeatability and minimal thermal distortion. Furthermore, it facilitates consistent quality across entire production batches, which is critically important in industries where tool performance and longevity directly impact manufacturing efficiency and cost.

CEIA’s induction systems (induction heaters), which often integrate an induction coil or induction heating coil as part of their design of an induction heater, are frequently selected for tool brazing applications due to their compact physical design, precise power control capabilities, and outstanding energy efficiency. When seamlessly integrated with advanced control units, these systems robustly support consistent heating cycles, optimize filler flow dynamics, and effectively mitigate the risk of localized overheating or the formation of substandard, weak joints. The result is a consistently brazed component